ROBOTS

End Effectors

Kensington’s Robot End-Effectors have a long history of operation in semiconductor wafer fabrication. Several of Kensington’s End-Effector innovations have advanced wafer processing capability. These include 300mm Edge-Grip for reduce particle performance and Through Beam Technology for wafer mapping. End-Effectors are used across the semiconductor equipment spectrum: Metrology Systems; Deposition Systems; Etch Systems; Reticle Process Systems; Thermal Processing Systems.

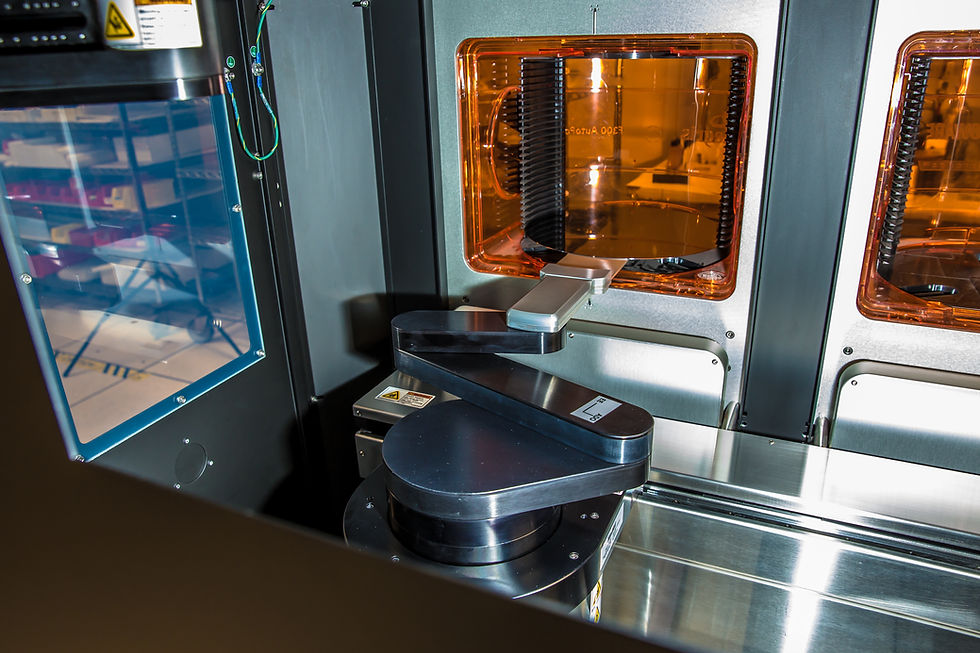

Pre Aligners

Kensington’s Pre Aligners have a long history of operation in semiconductor wafer fabrication. Several configurations of wafer aligners are available that support wafer sizes from 50 mm to 300 mm. The pre aligner technology is available in stand alone units as well as integrated directly into robots. The alignment technology is used for opaque as well as transparent materials and the wafer aligner supports substrates that are not round. Pre Aligners are used across the semiconductor equipment spectrum: Metrology Systems; Deposition Systems; Etch Systems; Reticle Process Systems; Thermal Processing Systems.

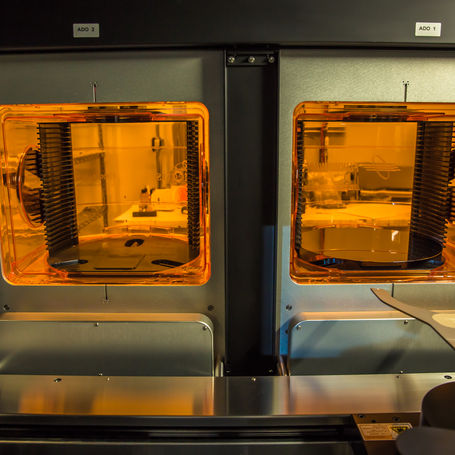

MultiLink SCARA Wafer Robot

Kensington’s Atmospheric MultiLink SCARA Wafer Handling Robots have addressed the needs for semiconductor wafer and quartz substrate handling for more than a quarter century. Key innovative features developed for semiconductor robot wafer handling : Through Beam Wafer Sensing; 300mm Edge-Grip End-Effector : Robot Self-Teach Functionality. MultiLink SCARA wafer robots are used across the semiconductor equipment spectrum : Metrology Systems; Deposition Systems; Etch Systems; Reticle Process Systems; Thermal Processing Systems.

ABOUT US

To aid customers’ operational and bottom-line success, Kensington supports the installed base with spares, repairs, upgrades and refurbishments. Kensington’s Spares & Repairs programs help customers avoid capital equipment obsolescence and postpone the purchase of replacement equipment. By keeping equipment in optimum operating condition, these programs extend operating life of the equipment and its ability to deliver maximum bottom-line performance. The company has a proven history of exceptional customer service and is structured to support equipment with operational lives as long as 20 to 50 years.

Contact Kensington for proven, robust products and solutions to enhance the performance and reliability of your products or to increase the operating life of equipment which already uses Kensington products.

REPAIRS & SPARES

CUSTOMER COMMITMENT

Kensington is committed to providing the most reliable and innovative wafer handling robots and precision motion control stages, we put or guarantee on every product we touch.

CONTACT

Inquiries

For questions about Kensington Laboratories, Kensington Robots, Kensington Stages, repair and refurbishment services and Newport PM500 products, please use the following contact information:

Head Office

Kensington Laboratories, LLC

6200 Village Parkway

Dublin , CA 94568

Phone: 510.324.0126

Fax: 510.324.0130

SALES

Kensington Robots & Stages, Newport PM500 Stages, Spare Parts

SERVICE

Kensington robot and stage repairs, Newport PM500 stage repairs